4500psi High Pressure Air Compressor for PCP

- Automatic stop

- 220v working voltage

- 4500psi working pressure

- Oil-water separation

Our Products

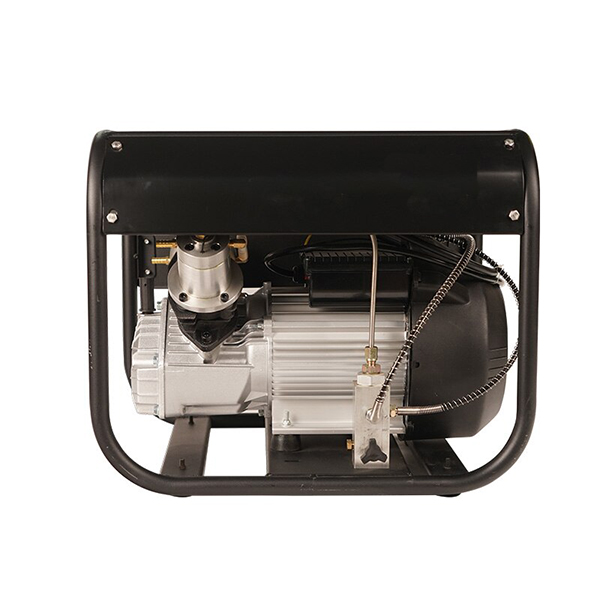

Topa’s 220V PCP air compressor, equipped with a dual compression system, significantly enhances air filling efficiency for superior performance. Featuring an integrated oil/water separator, it delivers clean, uncontaminated air, ensuring the compressor operates at peak efficiency and durability.

Furthermore, its auto-stop functionality allows for the presetting of desired pressure levels, automatically halting the pump once the set pressure is achieved. This not only saves time but also enhances safety by preventing overloading, making Topa’s high-pressure air compressor a reliable and essential tool for various high-pressure air needs.

Best Air Compressor for PCP

Adopt water cooling system

Air Compressor 220v

High working efficiency

High-pressure PCP Air Rifle Compressor

4500psi Working pressure

Air Compressor for PCP

Oil-water separation

Features of Air Compressor for PCP

High-Performance Compression

Our 220V PCP compressor is engineered for efficiency, featuring a robust dual-stage compression system that significantly boosts the air filling process. This advanced design ensures rapid, consistent air delivery, making it capable of charging a 6.8L tank to 300bar in under 30 minutes. Its performance is optimized for both speed and reliability, setting a new standard for high-pressure air compressors.

Unparalleled Purity with Integrated Filtration

Equipped with a state-of-the-art oil/water separator, our compressor delivers exceptionally clean air. This integrated filtration system removes impurities, ensuring that the air supplied is not only dry but also free of oil and particulate matter. This feature is crucial for maintaining the integrity and longevity of sensitive equipment, providing peace of mind for users across all applications.

Intelligent Auto-Stop Functionality

Designed with user convenience and safety in mind, our compressor includes an intuitive auto-stop feature. This allows users to preset a specific pressure threshold, after which the compressor will automatically cease operation. This smart technology prevents overfilling and internal damage, ensuring a safe and efficient compression cycle every time. It epitomizes our commitment to delivering user-friendly, technologically advanced solutions for all high-pressure air needs.

Wide Application of 220v PCP compressor

Scuba Diving and Dive Tank Filling

The 220V PCP compressor’s ability to rapidly fill tanks up to 300bar makes it an invaluable tool for scuba divers. Its efficiency in refilling dive tanks ensures that divers have a reliable air supply, significantly enhancing their underwater exploration experiences. The clean, dry air provided by the integrated oil/water separator also helps in maintaining the quality and safety of the breathing air in dive tanks.

Paintball and PCP Air Gun Enthusiasts

For paintball enthusiasts and PCP air gun users, the 220V PCP compressor offers the convenience of quickly refilling air tanks, ensuring that the action never stops. The compressor’s rapid filling capability, coupled with its portability, makes it an essential piece of equipment for powering paintball guns and PCP air rifles, providing a consistent and reliable air supply for competitive and recreational use.

Industrial Testing and Quality Control

The compressor’s precise pressure control and auto-stop functionality make it an ideal solution for various industrial testing applications, including leakage tests, pressure resistance checks, and airtightness testing. Its ability to deliver clean, dry, and consistent air is crucial for ensuring the integrity of pressure-sensitive components and systems, making it a valuable tool for quality control processes in manufacturing and engineering sectors.

Quality 220v Air Compressor Manufacturing

Topa’s airgun compressors, including our custom models, have achieved CE, ISO, and TUV certifications, ensuring free circulation throughout the European Economic Area (EEA). Our commitment to quality extends beyond our products, encompassing every service we offer and our management processes.

Raw Material Control

- We exclusively use stainless steel and copper, conducting a 100% inspection before factory entry.

- Material certifications are provided to verify quality.

- Quality Control (QC) conducts thorough checks on size and quality for each material.

Process Control

- Inspections are carried out on all assembled units.

- We implement a dual-check system, including self-checks and peer reviews, to maintain high standards.

- QC oversight is constant in every procedure, with spot checks conducted throughout the process.

Finished Products Control

- Every product undergoes a 100% testing protocol.

- Post-assembly, we conduct rigorous air leakage and pressure tests to ensure integrity and performance.

Packing Control

- Each product is securely packaged in foam boxes to prevent damage.

- Fragile labels are affixed to each case to ensure careful handling.

- QC performs a final review of the product and includes an Out-going test report with each shipment.

More Manufacturing Process for Topa Air Compressor for PCP

CNC Machining of Compressor Cylinder Head

Precision machining of the cylinder head using CNC technology ensures exact dimensions and a perfect fit for efficient compression.

Assembly of Low-Pressure Cylinder and Internals

The low-pressure cylinder is carefully assembled with internal components, ensuring seamless operation and optimal air flow.

Motor Installation for Airgun Compressor

A high-performance motor is installed, providing the necessary power to drive the compressor effectively.

Encasing the Compressor in its Shell

The compressor’s mechanical parts are encased within a durable shell, protecting the components and ensuring user safety.

Compressor Functionality Testing

Rigorous testing of the compressor is conducted to verify its performance, including air output, pressure accuracy, and operational stability.

Material Preparation and Cutting

Raw materials are prepared and precisely cut to specifications, ensuring the quality and integrity of the compressor components.

Packaging of the Airgun Compressor

The compressor is securely packaged with protective materials to prevent damage during shipping, ensuring it arrives in perfect condition.

Installation of Spare Parts

Spare parts are installed as needed, ensuring the compressor is ready for immediate use and providing users with a complete solution.

Why Choose Us

Topa, as a company specializing in the manufacture of PCP filling fittings, always treats every customer with a proper service attitude.You will experience a good shopping experience at Topa.

Customized Service

If you don’t find what you’re looking for on Topa’s shopping site, you can contact our sales of your needs and we’ll provide customized service until you find your final solution.

Strict Quality Testing

Topa treats every product produced with high standards. Every product you receive has been rigorously tested before being sent to you, so you can rest assured that it will be used with confidence.

Professional Product Knowledge

Topa’s sales are familiar with every product the company manufactures, are trained in product knowledge and has a deep understanding of the products.

Many Years of Manufacturing Experience

With over 10 years of experience in manufacturing PCP filling fittings, Topa has acquired a great deal of knowledge on how to produce high-quality products.

Related Product

In addition to the air compressor for PCP, topa also produces other PCP filling products that are made of high quality materials and have excellent performance, such as: PCP air compressors, PCP air pumps, filling stations, PCP air filters, PCP fill probe, etc.You can get more information about other products by clicking on the links below.

FAQs

Could I use Topa's PCP air rifle compressor on a tire too?

No,you can’t use 200v air compressor on tires.A PCP air rifle compressor that provides too high pressure to blow your tires.

What is the best oil to use for Topa's PCP air rifle compressor?

You just need high-quality hydraulic oil for Topa’s PCP air rifle compressor.

Does Topa's air compressor for PCP have an adjustable pressure stop?

Some air compressor for PCPs made by Topa have an automatic stop,while others do not.

Does Topa's air compressor for PCP come with an oil/water separator?

Yes,Topa’s air compressor for PCPs come with an oil/water separator.

Does Topa's PCP air rifle compressor run off a normal wall outlet?

Yes,Topa’s PCP air rifle compressors can run off a normal wall outlet.

Can I use Topa's PCP air rifle compressor with a paint gun with a regulator?

No,you can’t. This compressor is designed for extremely high pressure,you can’t use Topa’s air compressor with a paint gun.

Can I use a battery to power the air compressor for PCP?

No,you can’t. A battery does not have the AMPs to run the air compressor for PCP.

Is Topa’s air compressor for PCP a self contained unit or do I need another air compressor to assist it?

You can use the air compressor for PCP on its own without any other air compressors.

Do I need to add water to Topa's PCP air rifle compressor?

Yes, Topa’s PCP air rifle compressor requires water for its cooling system to ensure optimal performance and longevity.

Does Topa's PCP air rifle compressor come with a warranty?

Yes, Topa’s PCP air rifle compressor comes with a warranty, providing customers with assurance and support for their purchase.