Why Choose Us

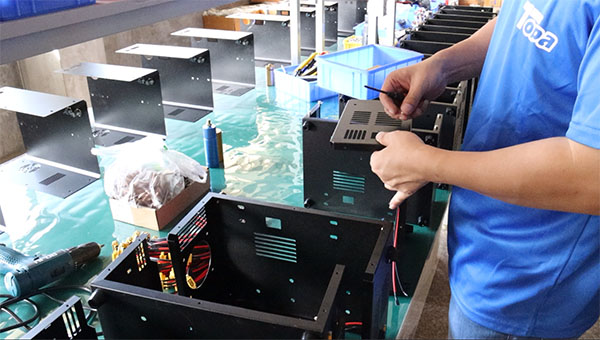

Topa has more than 10 years of experience in manufacturing PCP air compressors and has strict testing standards to ensure that we can provide the best quality PCP compressors to you.

Large Inventory

Topa can manufacture PCP air compressors of various sizes and also accept customization from customers. Our inventory is very well stocked to meet your large demand for PCP air compressors.

Professional and reliable

Topa’s many years of experience have allowed Topa to accumulate a lot of expertise and manufacturing know-how about PCP air compressors, which enables Topa to provide you with professional services and reliable products.

Fast transportation

Topa can offer you a wide range of transportation options, so you can choose between air, road, or water transportation, depending on your situation.

Professional customer service system

Topa’s customer service staff is professionally trained and has a deep knowledge of the PCP air compressor, you can contact us with any questions you may have about the PCP air compressor. We remain at your service 24 hours a day.