What is a PCP pump

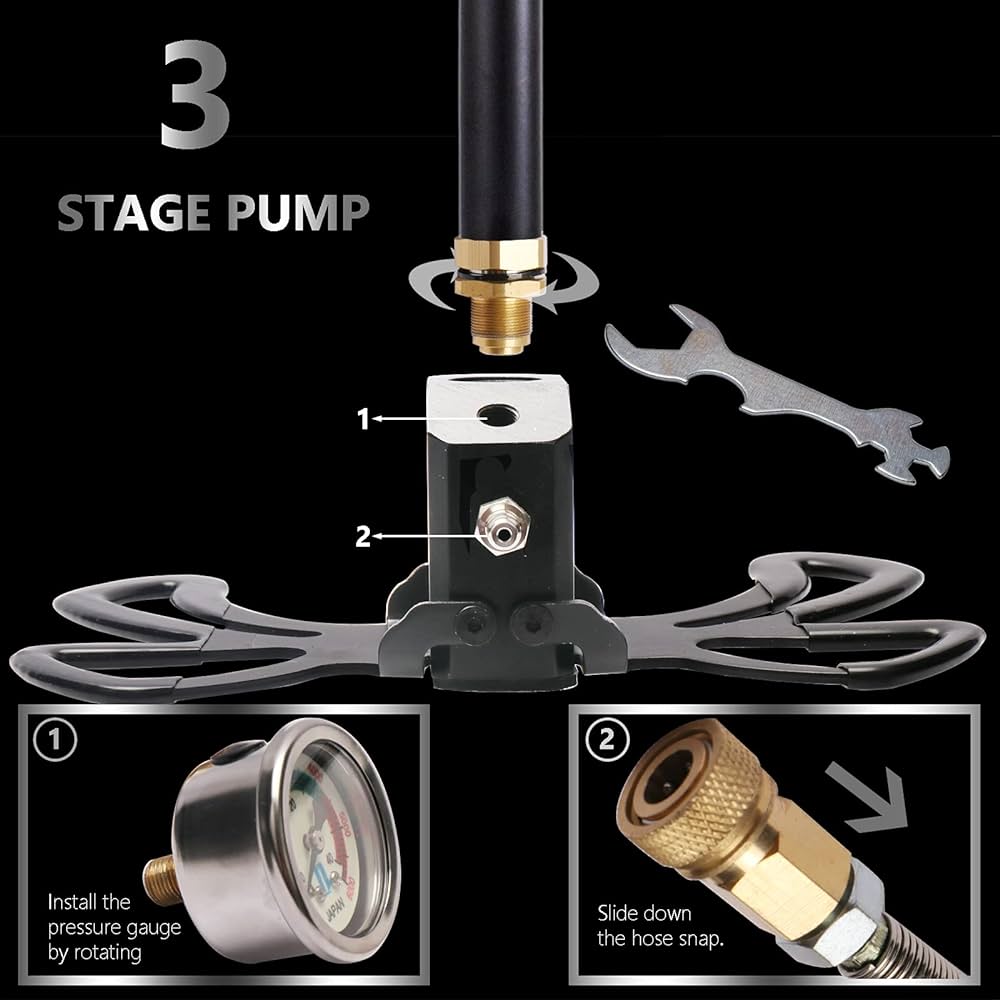

What is a PCP pump What is a PCP pump Table of Contents Introduction When discussing PCP air pumps, one variant that often garners attention is the PCP Hand Pump. Unlike its electric or gas-powered counterparts, a PCP Hand Pump is manually operated, offering a cost-effective and portable solution for filling air tanks. Its basic […]